Ever wondered what antistatic bags are, how it's made, what it is used used for and where to buy antistatic bags at cheap low prices. Find answers to all your question on antistatic bags or static sheilding bags here.

If you need a specific size, thickness, colour or print, on antistatic bags then please write or call to our top supplier who will give your inquiry immediate and personal attention, helping you to get the answers you need right.

|

Transparent pink bag that protects sensitive electronics from damage caused by the harmful effects of static electricity. Static travels around the bag and dissipates before it has a chance to damage contents when shipping or storing. These bags are usually plastic and have a distinctive color (silvery for metalized Mylar and other similar plastics, pink or black for polyethylene). The polyethylene variant may also take the form of foam or bubble wrap, either as sheets or bags. |

|

|

|

Flat Anti-Static Poly BagsProtect electronic components from static build-up. Constructed from pink anti-static polyethylene film. Keeps products clean and moisture free. |

|

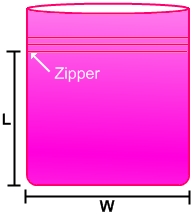

Gripseal/Zipper Antistatic bagsThe same properties as the Open Top(Flat) Pink Poly Bag plus the security and convenience of a zipper top. The zipper top closes securely to protect against damage from dust and moisture. |

|

Anti-Static Poly TubingMake your own anti-static poly bags. Excellent resistance to static discharge. Static dissipative, non-corrosive pink polyethylene is heat sealable. Seal with Poly Tubing Sealers. |

|

Anti-Static Bubble Bags or Bubble pouchesProvides maximum protection against static discharge for circuit boards, relays, switches, resistors, controls and other static sensitive electronic components - Apply your own labels. 3/16" Industrial bubble coated with a nylon barrier provides outstanding cushioning. 1" pressure sensitive lip covered with release paper allows for easy closing. |

|

Question. I have two questions about one material. Anti-stat bags.

1. How effective are anti-stat bags with a relative humidity of less than 20 % and temperatures as high as 110 degrees Fahrenheit.

2. How do you put a spec on an anti-stat (ohms/sq. etc.) bag to ensure maximum protection and re-use?

Answer.The clear static dissipative polyethylene (PE) that high quality vendors use in their bags is far superior than the "topically treated washed" pink poly products.

Dissipative and metallized shielding bags are made with volume loaded polyethylene which cannot be washed off and is inherent in the film. The PE resin that we use and all the additives are developed to minimize contamination.

The antistatic dissipative clear bags are pre-conditioned and tested at both 50% and 12.5% RH levels to have a surface resistivity of less than 1x10^11 ohms. (old nomenclature = ohms/square)

Testing:

You can perform two test to ensure the proper operation of the bags:

1. perform a resistance test on the bag film to < 1x10^11 ohms @100 volts [using two five pound electrodes and megohmeter per esd s11.31-1994 and esd ds20.20-1998]

2. perform a tribocharge test, yielding static decay of less than or equal to 140 milliseconds, per FTMS 101C, Method 4046

Question. What is the recommendation or guidelines in determining when Anti Static shielded bags are no longer any good, i.e. crinkled or have small puncture holes, and put out of service?

Answer.All your answers are in the MIL-B-81705C Standard document. Specifically, an anti-static shielding bag (type III) can be considered no good if it meets any of the following conditions:

In general, a metallized shielding bag may still shield if it has crinkled or acquired small holes because of the Faraday affect, but it is safer to discard these bags and err on the conservative side. It would probably cost more to test and qualify the bag then to replace it.

Question. In my company many rolls of bubble wrap, plastic bags, and PCB boxes (plastic cases) are listed as "Anti-static". While we all understand that these items will not produce serious static, many think that they will also protect the components inside from a static charge. My contention is that a significant amount of charge would pass through the bag/box and damage any ESDS item inside. Only a shielded bag would guarantee complete protection from ESD. The question really arises because a well-known and respected PCB manufacturer sends their PCBs� to us in anti-static plastic cases. The clear plastic case only lists "Anti-Static and we can not see any conductor strands within the plastic. What are your thoughts?

Answer. There are two ways to protect ESDS PCBs. One way is by shielding. The use of metallized shielding bags is a good way to protect the contents from external ESD. Another way to protect ESDS PCBs is to isolate them from external ESD with an air gap. There are "clam shell" packaging and other anti-static plastic packages that will give a spacing of about an inch of air between the outside plastic shell and the ESDS part inside. This "air gap" spacing can be an effective way to protect ESDS parts from external ESD as a 1" air gap acts as a dielectric to prevent discharges up to 30 kilovolts.

The evolution of the ESD-control bag and packaging-material design has been a compromise between various features. Ideally, you look for ESD bag materials that combine low cost with properties such as high ESD shielding effectiveness, permanent antistatic properties, humidity-independent performance, elimination of contamination and corrosion, MVB properties, heat-sealability, and transparency.

Traditionally, static-shielding bags are manufactured by depositing a thin metal coating such as aluminum over an antistatic polyester film substrate. The metallized layer protects the devices in the bag from electrostatic fields; the insulative layers prevent direct contact with potential ESD hazards. At the low end are amine-free, polyethylene film bags that are transparent or pink in color, referred to as antistatic or pink poly.

Over the past years, manufacturers have developed a number of static- dissipative materials that minimize tribocharging and improve puncture resistance and durability. Durability is a particularly attractive property in most ESD bags where sharp-edged PCBs are loaded into the bags.

Manufacturers also are developing more environmentally friendly materials than they had in the past. Historically, ESD protective packaging has environmental problems similar to any plastic material: disposal and material decomposition can present an environmental hazard. Recently, manufacturers have conquered some of the disposal problems, and we now see more recyclable ESD bags on the market, such as those made from polypropylene.

Let�s review the current technology for ESD bags. There are essentially three types or categories: antistatic bags, dissipative bags and metallized bags. The latter two categories are typically the high-end of ESD bag product offerings and tend to have three combined properties of protection, (1) antistatic, (2) dissipative and (3) shielding.

Because we mentioned antistatic grip seal bags and antistatic bubble bags we thought these websites to be useful for more information about each of the bags.

Please visit www.discountselfsealbags.co.uk for grip seal bags.

Please visit www.bargainbubblebags.co.uk for bubble bags.